Scanning / X-Ray

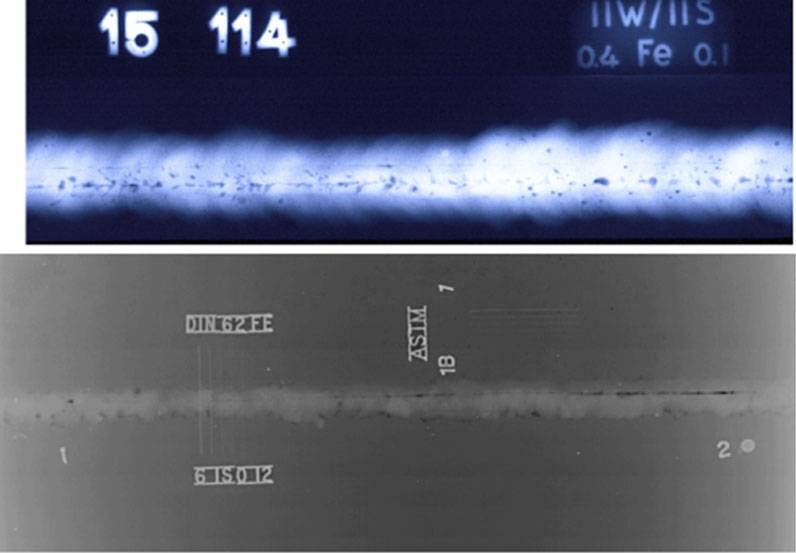

Radiographic testing is a non-destructive testing technique to detect volumetric discontinuities in welds, castings and parts in general, where radioactive sources (usually called gammagraphy) or X-ray devices are used. It results in the recording of discontinuities on radiographic film.

Radiographic testing is a non-destructive testing technique to detect volumetric discontinuities in welds, castings and parts in general, where radioactive sources (usually called gammagraphy) or X-ray devices are used. It results in the recording of discontinuities on radiographic film.

This test is applicable to a large number of materials with different densities and thicknesses. X-ray is used in many industries such as energy, oil and gas, aviation, marine, construction, etc.

Radiographic testing is a non-destructive testing technique that stands out for its main characteristics:

- It generates permanent records.

- It identifies defects that would not appear through other tests.

- Easy understanding of the defect and its origin.

The test is carried out using radioisotopes of Iridium 192 and Selenium 75, or by means of an X-ray generator. ISS RD, SRL uses shielded cameras models QSA DELTA 880 and QSA SCARPRO 1075 totally certified internationally for the handling of Iridium 192 and Se75 isotopes. We have 225 KV directional X-ray tubes for high quality welding work with low radiation exposure.

At ISS RD, SRL we have experienced inspectors with vast knowledge of radiological safety, duly certified by the National Energy Commission, Nuclear Division of the Dominican Republic and licensed to operate in the national territory. In addition, we have our practice of non-destructive testing of industrial radiography (ASNT RT Testing) with ASNT RT Level II and Level I inspectors with more than 20 years of experience in the evaluation of defects. All our inspectors and industrial radiography program is endorsed and certified under the scheme of the American Society for Non-Destructive Testing (ASNT) and certified inspectors ASNT RT Level III.