UT for Thickness Measurement

Ultrasound (UT) is a NDT technique considered to be volumetric, which means that it has the capacity to evaluate an inspection area in three dimensions.

Although thickness measurement technology can be applied to different materials and at different stages of the production process, it is in great demand when evaluating equipment in service. Although there are many damage mechanisms that affect the different equipment in a plant, internal degradation phenomena that can affect the design thickness in tanks, pipes and pressure vessels are of great concern in industrial complexes because of the social and economic impact caused by possible leaks.

The thickness measurement technique allows to find degradation zones on internal surfaces, caused by corrosion phenomena, abrasion-corrosion phenomena among others. From the information provided by the UT technique, the integrity engineer can calculate corrosion rates, estimate useful life time and next inspection periods.

At ISS RD, SRL we have experienced inspectors with a vast knowledge of ASTM standards and building codes such as ASME, AWS and API codes and with certificates as ASNT level III and level II inspectors in the Ultra Sound Technique (UT), certified under the scheme of the American Society of Non Destructive Testing (ASNT).

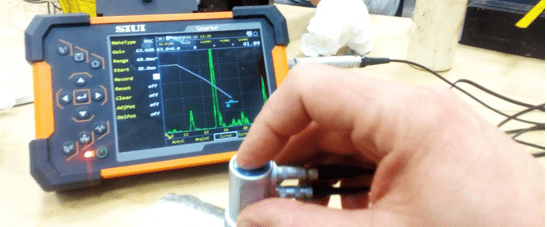

We also have a wide variety of portable and easy-to-handle equipment, which allows fast and reliable measurements, with A-Scan and B-Scan displays. We work with Olympus, SIUI and Danatronics equipment. We have a great variety of single-crystal and dual probes with a variety of diameters ranging from 6mm to 25.4 mm and frequencies from 1 Mhz to 10 Mhz, allowing great versatility for testing on a wide variety of surfaces and working temperatures. Additionally, we have a robotic magnetic equipment "Crawler" that allows us to access areas that only an inspector with scaffolding systems could access, such as tanks, chimneys and others.