Boroscopy

One of the first natural methods of any test we use is visual testing. Almost any specimen can be visually determined for size correction, completeness, number of parts, and manufacturing accuracy. In many cases visual inspection will eliminate the need for more sophisticated non-destructive testing for these samples. Visual testing can locate portions of the sample to be inspected later by other techniques.

One of the first natural methods of any test we use is visual testing. Almost any specimen can be visually determined for size correction, completeness, number of parts, and manufacturing accuracy. In many cases visual inspection will eliminate the need for more sophisticated non-destructive testing for these samples. Visual testing can locate portions of the sample to be inspected later by other techniques.

The application of visual testing requires eye contact with a portion of the sample to be inspected, adequate illumination of the sample, and some sample specifications. Our certified technicians are prepared to provide the best possible evaluation of your equipment with this technique.

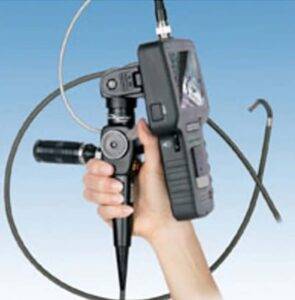

ISS RD, SRL uses the latest generation of borescopes to inspect hard-to-reach areas and for the inspection of high-purity welds. We have highly trained technicians for pipe or equipment inspection with the ability to electronically store the data obtained for future reference and defect analysis.